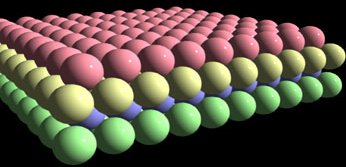

Super Therm® Molecular Scientific Structure

Super Therm® contains two reflective ceramics that act to deflect radiant heat and reduce surface heat build up. A third ceramic stops hot/cold conduction by providing a microscopic dead air space between the surface and substrate. In the foundation, two acrylic resins provide elasticity, adhesion and water resistance. A third urethane resin creates a moisture and ultraviolet barrier.

The last polymer additive ensures a slow drying time to prevent cracking as well as add a silky finish. The resin/ceramic combination has been shown to reflect both heat and fire, withstand elements for 30 to 40 years, endure 180° temperatures, bend without cracking, and resist water and ultraviolet light.

Source: American Temperature Control

The HEAT LOAD falling on a surface is key to the need for insulation and also determines the amount of heat which will be transferred on into the building.

If the initial HEAT LOAD is reduced then the amount of heat transferred inside the building by conduction or convection is also automatically reduced and this enables the reduction of the thickness of insulating layers, which is crucial for standard batting or foam insulation.

Standard insulation materials are subject to up to 100% of the initial heat load from the heat source and therefore their thickness is determined depending on the amount of heat they can retain, and thus retard HEAT TRANSFER into the building. Super Therm® works on the principle of handling the initial HEAT LOAD arriving at the surface, and thus the thickness of the insulating layer is not crucial.

Super Therm® has demonstrated that its reflectivity can reduce the initial radiative heat load falling on a surface by 95%. This means that roofs or exterior walls will be burdened by only 5% of the HEAT LOAD which is attempting to be transferred on into the building. So, after coating, the building will be subject from the start to only the residual heat load, whose further transfer through the structure by convection or conduction Super Therm® blocks as well.

Standard insulation materials must absorb up to 100% of the HEAT LOAD and therefore depend greatly on their thickness, because the thickness determines the length of time over which they can prevent heat transfer into the building by retaining it. Therefore, Super Therm® can’t be compared to classical insulation based on R-value or K-value, which are calculated based on the thickness of the material.

Super Therm® is designed so that it blocks the initial heat load and then handles only the residual unreflected heat. It is not designed to absorb the entire heat load as does classical insulation, where accumulated heat gradually leaks into the building even at night.

Super Therm® is mainly used, therefore, as a peerless, highly-effective means to block direct solar radiation and its transfer to the building and to prevent the serious 21st-century problems of global warming.

Stir Super Therm® thoroughly for a minimum of 5 minutes

While NASA where trying to develop a heat shield for space shuttles in the 1980s they worked to develop thermoceramic technology resisted extreme heat fluctuations due to the extreme heat on re-entry to the earth’s atmosphere.

On the basis of this the manufacturer Superior Products International II Inc. collaborated on their main product Super Therm® with the research centres (NASA). Successful development of the coating with inimitable characteristics succeeded in particular thanks to collaboration of the scientists and ceramic engineers from Marshall Space Center (NASA).

After 2 years of testing more than 600 different kinds of ceramic components, 3 ceramics were identified with the greatest ability of radiation reflection and the smallest heat conductivity were ultimately selected. Later researches proved inevitability of blocking also infrared radiation. Therefore the fourth ceramic compound was added. Applying knowledge from space environment a unique thermoceramic (multiceramic) coating for civil usage was created. J.E. went on to test over 4,000 different ceramics to lock in the ultimate solar heat block insulation coating in the world proven for 30 plus years.

SPI II Inc., accomplished their most important task – the coating provided not only heat reflection like other ceramic “heat – reflecting” coatings on the market but also blocked most of the heat transfer making it unique!

SPI II Inc., accomplished their most important task – the coating provided not only heat reflection like other ceramic “heat – reflecting” coatings on the market but also blocked most of the heat transfer making it unique!

Super Therm® thus contains not only one reflecting ceramic compound, but four different ceramic compounds:

The four ceramic compounds enables Super Therm® to be a real “solar heat block” and not only a “heat reflector” like common ceramic coatings. Super Therm® was tested and applied in NASA Space Flight Center as the only commercial thermoceramic coating. The developers of Super Therm® rely upon the latest scientific research of ceramic technologies.

High-performance thermal reflection + low absorptive emissivity + high radiative emissivity + conductive resistance = the outstanding thermal protection Super Therm®

The principle of operation of Super Therm® thermal ceramic coating is based on thermal reflection, very low absorptive emissivity and its ability to very quickly dissipate unreflected residual heat while simultaneously blocking its transfer to the surface beneath.

The essential ingredient of the coating is special hollow ceramic micro-balls 50-100 microns in size which give the material its thermo-reflective and thermal properties. Ceramic materials are very poor conductors of heat, and excellent insulators.

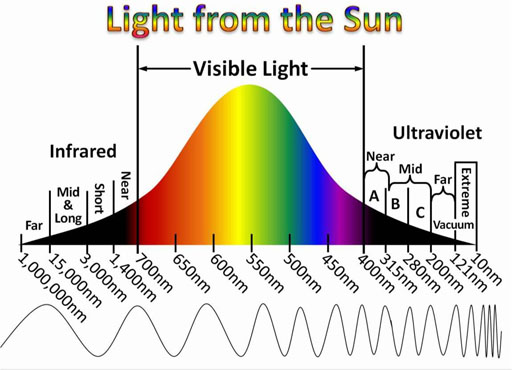

UV, IR and visible light heat causing spectrum – chemistryland.com

Every material absorbs some energy and reflects the rest back. Ordinary coatings or building materials reflect back only around 30% of thermal energy and absorb the rest into themselves. Moreover, as a result of their high absorptivity, heat accumulated in them over time leading to a gradual increase in temperature as it radiates through.

Super Therm® solar heat block coating reflects up to 95% of thermal radiation while blocking the passage of residual heat to the material beneath (roofs, walls, etc). Additionally, thanks to low absorptive emissivity, its surface temperature does not increase, remaining cool throughout the day relative to the ambient temperature.

Blocks 95% of Heat Load (blocks the absorption and transfer of heat – pdf test results)

1. Adsorptively and 2. Radioactively (in terms of the intensity of heat repulsion from the surface).

Absorptive emissivity (capacity to take in and retain thermal radiation) is given as a low rate of emission Radiative emissivity (capacity to dissipate thermal radiation) is given as a high rate of emission. Materials with matte black surfaces have high absorptive emissivity approaching the maximum limit of 1.0 retain a large volume of radiation.

In contrast, bodies with lustrous surfaces such as mirrors or burnished aluminium have low emissivities around 0.08 and thus retain practically no radiation within themselves.

Super Therm® has the incredibly low absorptive emissivity value of 0.05.

Maximum emissivity value is 1.0

Contrarily Super Therm® has very high (more than 95%, or 0.95 value) infrared radiative emissivity, meaning that it is extremely effective in shedding even the smallest amount of heat it might absorb.

The result is that even with day-long solar heating and 40°c temperatures, Super Therm® remains cool on its surface all day. This unique property differentiates it from ordinary ceramic and reflective coatings and therefore reduces heat load into buildings. Traditional fibreglass insulation absorbs the heat then releases it as the ambient temperature reduces around it.

The described thermoreflection, low absorptive emissivity and simultaneous high IR radiative emissivity are the basis of Super Therm®. Coating’s thermal heat block capabilities. Because the more heat is reflected repelled from the

surface, the less heat will be absorbed and flow to what’s beneath.

Furthermore, the special ceramic also impedes the flow of unreflected solar heat into the surface below. In tests, Super Therm® coating reduced the BTU conductivity of material from 350 BTU to 3.77 BTU (99.7% reduction).

Super Therm®, unique properties, especially its ability to keep surfaces cool even in extreme temperatures, enabled the coating to pass muster in the California “COOL ROOF” engineering research program with the highest marks.

Results from the COOL ROOF program:

Research in the roofing materials field has shown that increasing a surface’s solar reflectivity substantially increases the lifespan of the entire roof covering. Therefore, some asphalt roofing materials manufacturers began furnishing their products with lustrous metallic foil or painting them with a white or silver reflective coating. This has substantially protected their products’ surfaces against damage, yet not against heating.

At first glance it appears that the silvery, reflective aluminium paints work as perfect solar reflectors. This is not the case, though, as flakes of aluminium paint have high reflectivity to the visible solar spectrum yet their ability to hand infrared emissions is low. They do not repel infrared radiation, but absorb it.

Despite the fact that a mirror-polished silvery surface appears to us as the best heat reflector, in practice such a surface reflects only visible light rays: 40% in solar radiation and 3% in UV. The remaining 57% is made up of infrared radiation, which metallic surfaces do not reflect. And as they absorb that radiation, they heat up tremendously in a short time. This creates the overheating effect of the entire roof.

For these reasons, painting a roof as protection against heating with silvery aluminium or ordinary white reflective coatings is fundamentally ineffective. Only a ceramic coating with ceramic content repelling the whole spectrum of solar radiation is able to keep a roof surface cool all day. For this, Super Therm® is unmatched!

The difference is also in the durability of the reflective capabilities Ordinary reflective coatings lose more than 30% of their reflective properties in the course of 2 years Super Therm® coating lost only 0.01% of its reflective properties over the course of 3 years (more in the section on testing including the durability of reflective properties).

Looking to join one of the world’s leading coatings companies. Contact us if you’re a quality applicator looking for new products and markets!