Super Therm® effectively lower temperatures inside of buildings through heat load blocks, leading to reduced energy costs and less heat stress. When you talk about an 20-50% decrease* in energy usage that equates to a large amount of financial benefits long term. See how you can reduce costs with Super Therm®. If you’re looking for an effective and efficient solution to managing your energy costs, other running costs and improved comfort then Super Therm® is for you.

Super Therm® effectively lower temperatures inside of buildings through heat load blocks, leading to reduced energy costs and less heat stress. When you talk about an 20-50% decrease* in energy usage that equates to a large amount of financial benefits long term. See how you can reduce costs with Super Therm®. If you’re looking for an effective and efficient solution to managing your energy costs, other running costs and improved comfort then Super Therm® is for you.

Super Therm® is the least expensive professional permanent solution to heat block challenges. We have case studies showing a ROI in 1-3 years and 20-50% energy reduction. Super Therm® will be making money for you for a long time…OR…You can use the another paint, and use it again in two years, and again in two more years, etc…OR…You can do nothing and continue to pay higher utility prices. If you have solar panels you’ll also be increasing the cost benefits as less energy consumption means more power back to the grid for you. Contact us regarding prices!

Yes it is!

If you are ready to start reducing costs, be more comfortable, be environmentally conscious. Contact NEOtech Coatings Australia to get a quote, or place your order.

Super Therm® can be used to prevent heat load on most substrates and in most conditions. Super Therm® is extremely effective because it reduces moisture load into a substrate as well and air infiltration through a wall cavity, which substantially increases its value.

A: Some major international companies use and apply Super Therm® with some strong case studies from Japan:

Super Therm® is sold in 5 US Gallon pails = 18.9 litres. Average per litre costs increase on smaller quantities if decanted plus courier costs.

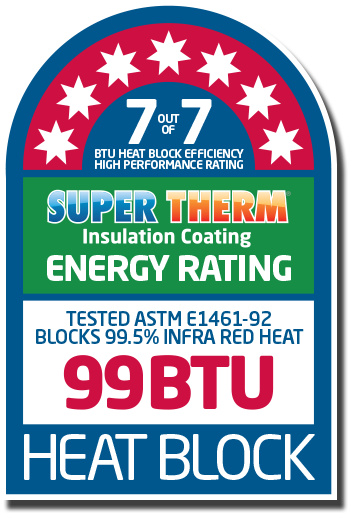

A: Yes. Tested by “COSMO Trade and Services” at the Japanese Institute of Technology in the window film and coating testing, Super Therm® blocked 99.5% of long range radiation (IR).

Super Therm® creates an energy efficient flat roof when used in a multi-layer system with Super-Base (HS) and Mastic Sealing Tape. Use Enamo Grip as a top coat.

Super Therm® has a tested emissivity of .91 which is the ability of the coating film to throw the interior convective heat off the wall and back into room to main interior heat. Super Therm® also blocks moisture load and airflow through walls/ceilings to allow heat to be lost or gained and block the airflow that carries warm air through structures. Super Therm® does breathe and will allow gasses and trapped moisture vapours to transmit for healthy and safe environments.

Super Therm® is not design as a conductive insulation so therefore does not have an R value. Heat block coatings are rating on BTUs. Super Therm’s BTU rating is 99.5% heat block:

A: Yes. Hot Box test and “Merrimac (pdf)” testing performed on shipping containers. A Heat Load test saw a reduction from 367.20 BTU down to 3.99 BTU into substrate.

A: Yes. Hot Box test and “Merrimac (pdf)” testing performed on shipping containers. A Heat Load test saw a reduction from 367.20 BTU down to 3.99 BTU into substrate.

The R-equivalent value is based on the ASTM C-236 hotbox, BTU conduction test, Merrimac (pdf) testing performed on shipping containers, and tests by VTEC Laboratories. Florida Energy Office (pdf) specialists performed these separate tests in three different parts of the United States. ASTM BTU reduction testing results saw a reduction from 367.20 BTU down to 3.99 BTU into substrate.

No. All current testing procedures in recognised laboratories are based on substrates and materials that offer a required minimum of thickness of 1 inch and assess only conductive heat transfer. The dry thickness of Super Therm® is 250 microns dry. The current formulas and equations are not adapted to such thin levels of insulation materials and do not consider radiational or convective heat transfer, moisture migration, air movement or surface emissivity. “Heat Load” is the key to heat absorption and then transfer. If heat load is reduced, then the amount of heat “available” for transfer is reduced and therefore affects conduction of heat which is the only measurement std UTL measure.

A: Yes. In the Thermophysical Research Lab report, the metal plate conducted 367.20 BTU’s, then with one coat of Super Therm® applied at 250 microns dry, the BTU conduction was reduced from 367.20 to 3.99. a 99.5% reduction after Super Therm®.

A: Yes, “SONY” engineering group performed testing on buildings. Result was 78% reduction on KW usage in a building which directly relates to dollars (KW times the cost of KW by the local power company).

Many other major companies have substantiated the results with their testing. Local fast food facilities with 25% cost benefits with only the roof coated and their grills in constant normal operation.

A: As some of the world’s largest corporations and government agencies that opted for Super Therm®, this is a strong indicator that it’s the market leader. Super Therm® will do the job for 30 years, it will protect even if you paint over it, it will cut your energy bills in half thus returning your investment within 3 years on average, and it will result in great cost reductions from there on.

Additionally Super Therm® is not like other ceramic coatings that yield a very rough finish do to their raw ceramics compounds. Super Therm® is manufactured with four different types of ceramics which are ground to perfect microscopic spheres, the formula is protected but you should know that the finish will be slight texture smooth, silky finish.

Independent tests have proven Super Therm® outlasts competitors and their reflective coatings. Which is why it’s part of the Energy Star Program. You would have to build an additional wall at least 8″ thick and fill it with fiberglass in order to match Super Therm®‘s heat block properties.

Super Therm® can be applied to a variety of surfaces on its own or with Super Base (HS) as a base coat for sealing. Surfaces include:

You can use a brush, roller, or an airless pot sprayer with a pressure of 1500 lbs/sq inch. The easiest way of knowing how much paint to use, is to select an area of 25m2 is 10 litres. With rollers you may have to apply the same amount in two coats this is due to the tendency of rollers to squeeze the coat too thin. The spread rate for Super Therm® is related to the thickness of the coating.

Instantly. In fact you will feel the difference immediately on application of Super Therm® as the structure will cool!

260°C continuously. If you need higher temperature protection see our HSC coating and for fire protection up to three hours our Omega Fire coating is the only coating to have passed ASTM E119 for three hours.

For each specialised application we have developed different heat block coatings, make sure you let us know how you plan to use it.

Yes you can use the rainwater caught from roofs covered with Super Therm®. We recommend that you disconnect any down pipes before application of the coating in the event that rain occurs. Let the first flush go down the drain and connect your pipes after 3 days after application.. The VOC of Super Therm® is 67 grams/litre making it safe according to Australian Standards.

Super Therm® comes in egg shell white, it can be tinted with water base dies to light colours by your local paint store. The cost to do this is minimum and you will have the local swatches to select the colours of your choice however there is a reduction in efficiency of the coating. The darker colours can cause a reduction in performance depending upon colour and environment. New infra red tints improve the performance of colours.

If you are ready to start getting the benefits, be more comfortable, be environmentally conscious. Contact NEOtech Coatings Australia to get a quote, or place your order.

The above information aims to support an effective management decision on the benefits of using Super Therm® as the primary heat block material. The proof category has been filled from every angle and certified by other major labs. This gives substantiation from other engineering groups and certified labs. *Results vary based on locations and climate.

Looking to join one of the world’s leading coatings companies. Contact us if you’re a quality applicator looking for new products and markets!